This is not investment advice. The author has no position in any of the stocks mentioned. Wccftech.com has a disclosure and ethics policy.

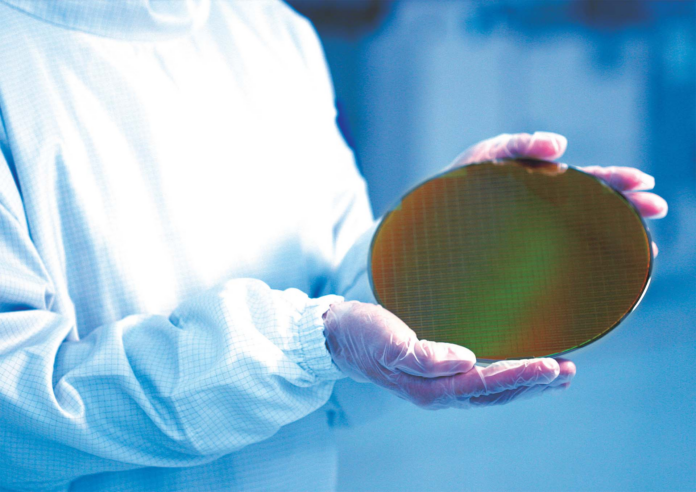

Korean technology giant Samsung is significantly slashing its chip fabrication investments, reports Business Korea. 2025’s start has marked the era of 2-nanometer chip fabrication, and according to today’s report, Samsung has decided to focus on its 2-nanometer and next-generation 1.4-nanometer manufacturing processes instead of expanding production of existing lines used to manufacture 5-nanometer and other technology products.

The report speculates that low yields and dropping orders are behind Samsung’s investment drawdown as the firm has decided to focus on next-generation products instead. The Korean firm’s lower investment grows the market available to Taiwan’s TSMC, the world’s leading and largest contract chip manufacturer.

Low Yields & Orders Influence Samsung’s Chip Manufacturing Investment Drawdown, Says Report

Samsung’s struggles with chip yields are among the most widely discussed topics in the media regarding chip fabrication. Right now, foundries are producing 3-nanometer products and Samsung had taken the lead in announcing production in 2022 of the advanced chip products. The production run marked an early stage in the process before mass production, and it saw Samsung ship 3-nanometer chips to a Chinese firm that designs cryptocurrency miners.

The Korean firm was vying for chip technology leadership back then, and its latest investment cycle appears to focus on this strategy as well. According to Business Korea, Samsung Foundry will invest 5 trillion Korean won in chip production in 2025, a 50% drop from 2024’s 10 trillion won.

The lower investment comes despite the fact that booming demand for AI products from firms like NVIDIA has expanded the addressable market for chip manufacturers like Samsung.

According to the details, Samsung’s latest chip manufacturing spending will focus on its facilities in Hwaeseong and Pyeongtaek. The Hwaeseong plant manufactures 3-nanometer chips, and the funds will be used to convert these lines to manufacture the next-generation 2-nanometer chips. Low yields have impacted Samsung’s foundry output, with multiple media reports claiming that the quality problems also affect the firm’s latest 3-nanometer chips.

A sizable chunk of global 3-nanometer demand comes from Apple whose smartphones, tablets and notebook computers all use chips made through the technology. Additional users include Qualcomm and other smartphone firms.

Samsung’s Pyeongtaek plant will focus on the next-generation 1.4 nanometer chip manufacturing process. This plant will be designated to product up to three thousand 1.4-nanometer wafers per month as part of a test production run. Samsung is also expected to allocate some of the funds to its chip manufacturing site in Taylor, Texas.

When compared to older chip manufacturing technologies, 2-nanometer products use newer transistor designs that aim to reduce current leakage and improve efficiency. Samsung’s 2-nanometer chips will use a gate-all-around (GAA) architecture, while TSMC’s products will rely on nano sheet transistors. Both firms are expected to start mass production of the products this year at their factories in Taiwan and Korea.

Samsung To Cut Chipmaking Investment By A Whopping 50% As It Struggles With Yields – Report

RELATED ARTICLES